Products

Products

solution and support

solution and support

contact

Contact

Precautions for the use and maintenance of plastic pallets

TIME : 2023/5/15 14:08:08

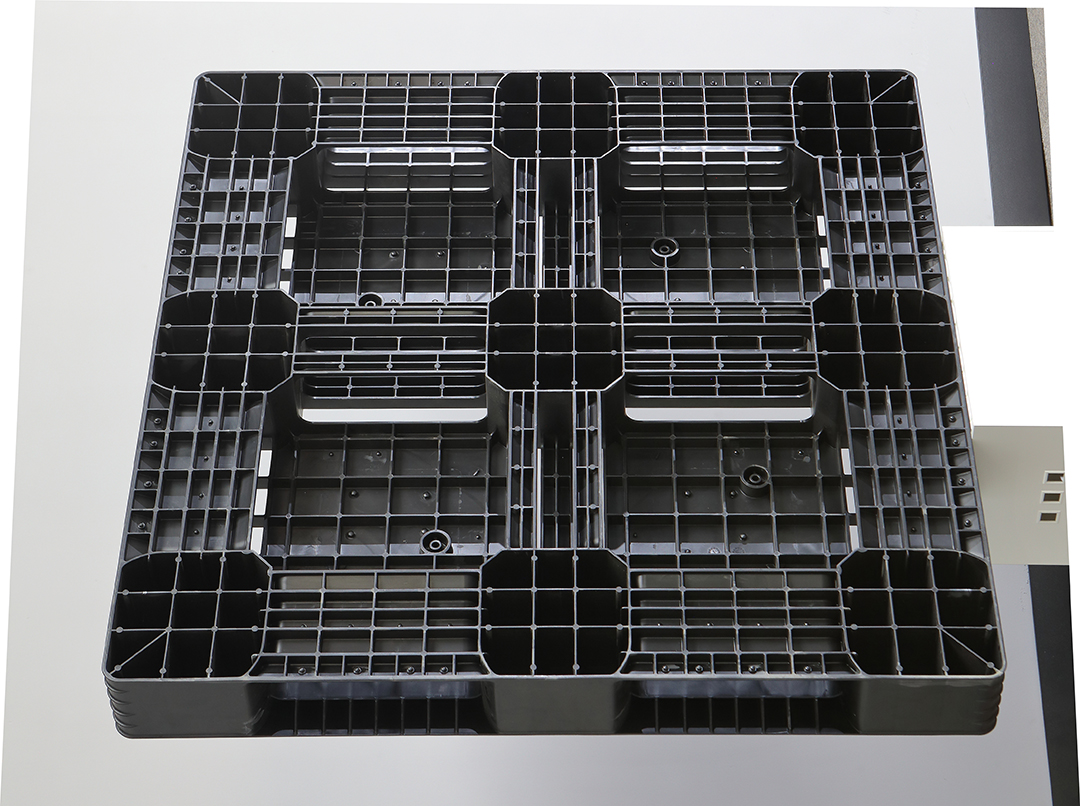

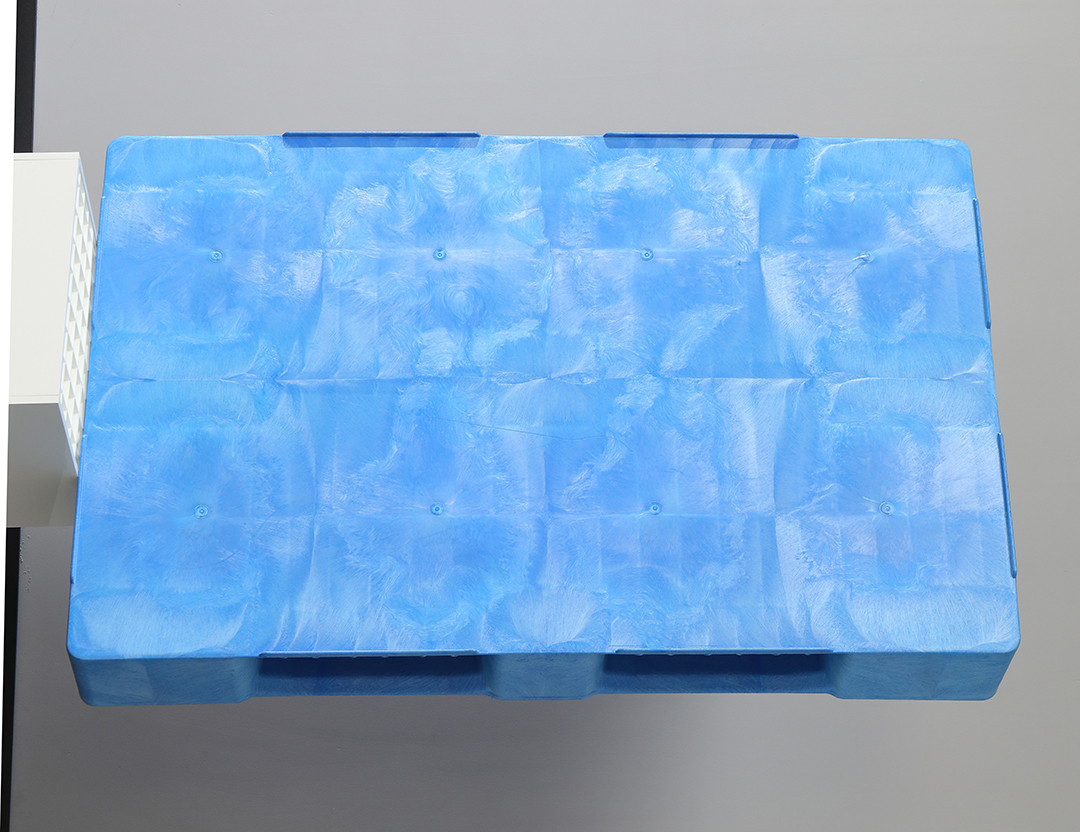

As an indispensable part of the warehousing and logistics industry, plastic pallets play a decisive role.If the plastic pallet is used in accordance with the correct use specifications, not only give full exert to its own function, but also extend its service life and reduce the procurement cost of plastic pallet.

The following points should be paid attention to when using the pallet:

1.The plastic tray should be handled lightly, so as not to damage the tray due to uneven force.

2.The goods should be placed smoothly to avoid side inclination during lifting and transportation.

3.When using handling equipment, it is necessary to consider whether the different size of the cargo is suitable for the plastic pallet to avoid inappropriate size.

4.When stacking, the weight of the bottom tray should be considered.

The correct use of plastic pallets should be the packaging combination on the plastic pallets, and appropriate binding and winding, easy to use mechanical loading and unloading and transportation.

In order to make plastic pallets safe for long-term use, plastic pallets can be used correctly according to the following requirements:

1.Plastic tray should be avoided in the sun exposure, so as to avoid aging, shorten the service life.

2.Do not throw goods into plastic trays from high places. Trays carrying heavy loads should be placed on flat ground or surfaces. Reasonable determination of the stacking of goods in pallets, goods should be placed evenly.

3.In order to avoid cracking of the pallet due to violent impact, it is strictly forbidden to throw the plastic pallet from a high place.

4.When forklift trucks or manual hydraulic carriers operate, the fork thorn should be as close to the outside of the fork holes of the trays as possible.The fork thorns should not touch the side of the tray to avoid breakage or cracking.The fork thorn should be fully extended into the tray, and the angle can be changed after the tray is lifted smoothly.

5.When the pallet is placed on the shelf, the shelf-type pallet must be used.The load is determined according to the structure of the shelf.

Kaihua founded in 2000.In the context of extending its business scope, Kaihua has invested 320 million RMB establishing Kaihua Logistics & Environmental Technology, as a subsidiary to focus on the development of logistics plastic injection moulds and products. With a total over 75000 square meters, Kaihua Logistics & Environmental Technology manufacturing plant will be able to provide premium products and services through its strong industrial design abilities, advanced mold flow technologies and high-quality mould manufacturing capabilities.

Currently, Kaihua Logistics & Environmental Technology is cooperating with IPL Group, Tri-wall, OTTO and Nongfu Spring for long terms.