Products

Products

solution and support

solution and support

contact

Contact

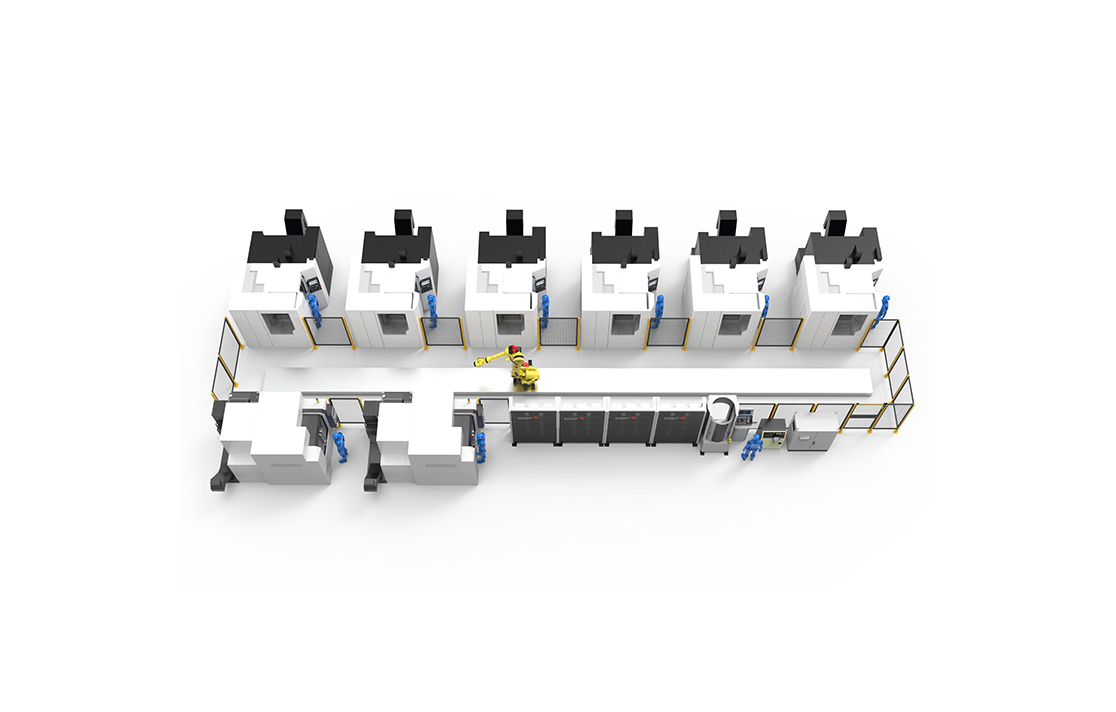

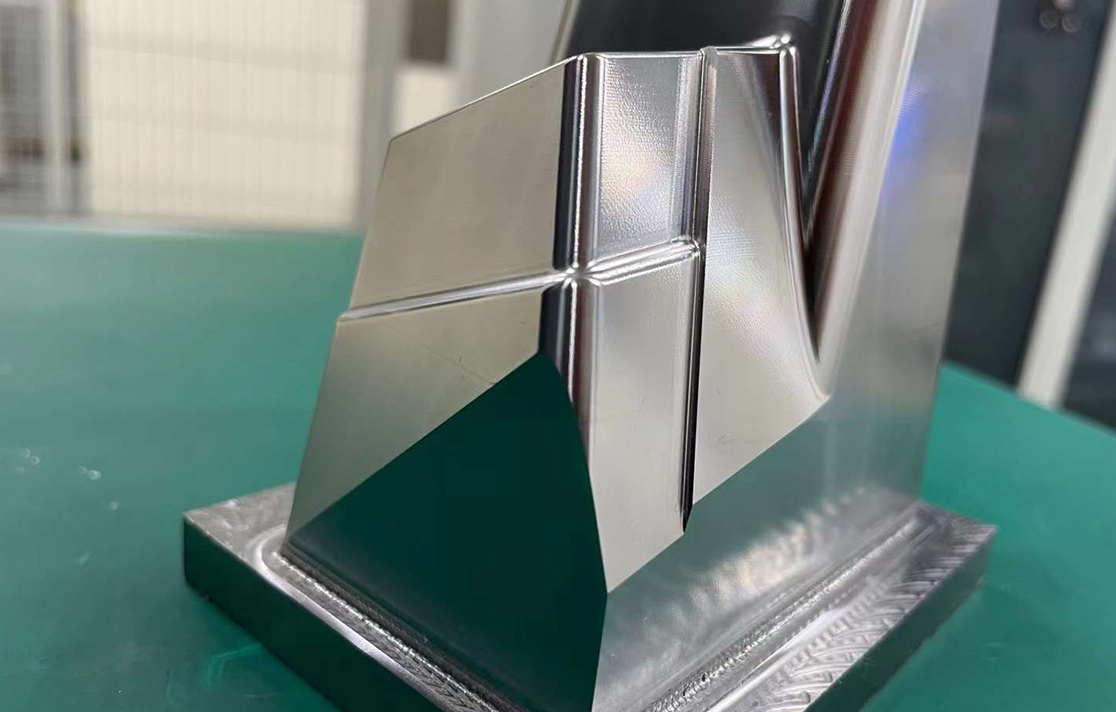

Small Steel Parts Automatic Processing Production Line

In order to optimize the production and processing course of small steel blocks and other parts, Kaihua Mould is equipped with a special automatic processing production line, which realizes the automatic processing and production of inserts, top blocks, inclined tops, small sliders and other parts. The production line effectively avoids the problem of out-of-tolerance that is easily caused by multi-process and multi-processing production processes, and also solves the problems of long standby time of production equipment.

The automated production line also has the following advantages:

lContinuous Automatic Production

Manual loading in advance, continuous production of machine tools, handling, clamping, positioning, program transfer operation, and machine tool processing and supervision are fully automated withutilization rate of 90% .

lReduce Human Risk

The parts can be put into the material library at will, and the robot will scan and determine the relevant information automatically. The machine tool parts program fixture adopts chip identification and binding to minimize human error.

lReal-Time Production State

In the process of processing, real-time monitoring is carried out, and the state of the parts is recorded and displayed on the display screen to show the state of the parts in the material library at any time.

lAnalysing Processing Data

All processed data are all included in the system, and the generated management report can be exported in real time.

SEND EMAIL TO US

SEND EMAIL TO US