Products

Products

solution and support

solution and support

contact

Contact

Products

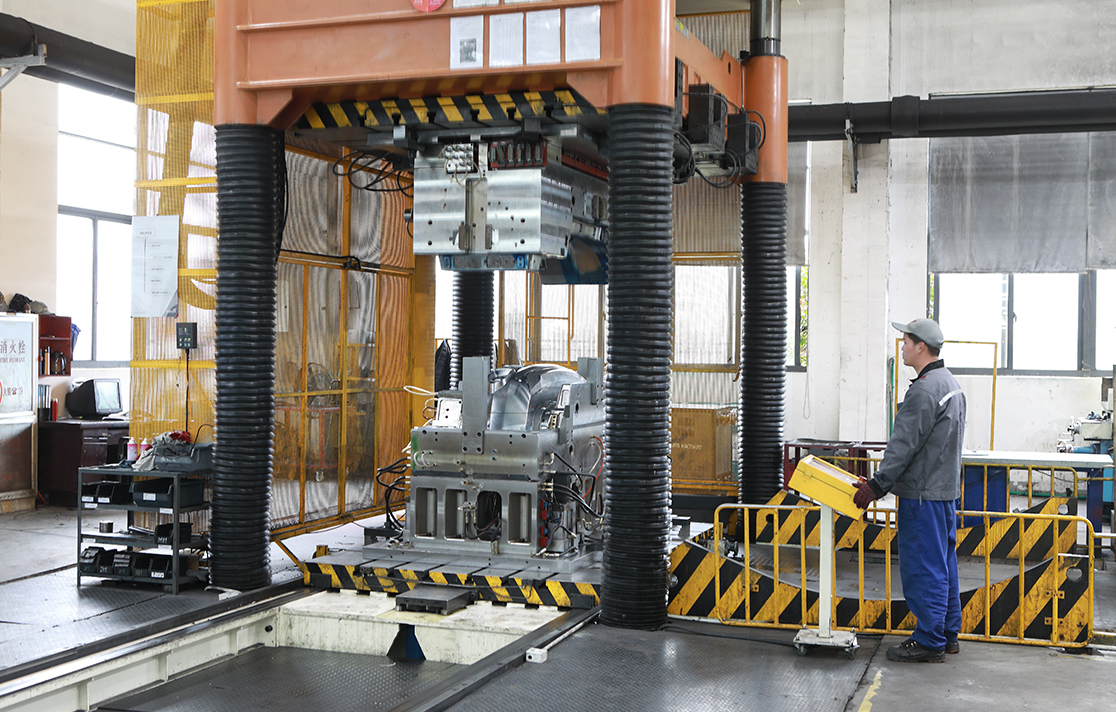

Die Spotting Machine

1.Product Introduction

The die spotting machine greatly reduces the number of dressing and grinding times by utilizing the reproducibility function of the machine. Testing of hydraulic slides, auxiliary cylinders and ejectors can also be performed in a single operation, featuring low operating and maintenance costs and high flexibility. The die spotting machine is more convenient to match the appropriate position of each part of the mold, check and realize the closure of the mold is more ergonomic, no longer use cranes, forklifts or lifting equipment and other dangerous ways to match the mold.

2.Advantage

lMaximum clamping force and table size can be customized according to customer requirements

lRotating table ensures the precision of multi-color die and improves the efficiency of die distribution

lAdvanced operation systen

lThe parallelism detection system protects the mold from damage

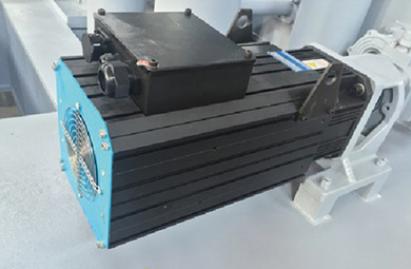

3.Detail

SEND EMAIL TO US

SEND EMAIL TO US