Products

Products

CNC Machining Center

5-axis High Speed CNC Machining Center

EDM

Hole Drilling Machine

Die Spotting Machine

Graphite Electrode Processing Machine

Grinder

Milling Machine

Plastic Crusher

Plastic Shedder

Granulator

Belt Conveyor

Automatic processing line of Small Steel Parts

Small Steel Parts Automatic Processing Production Line

Wire-Cutting Machine

solution and support

solution and support

contact

Contact

Products

Hot Runner

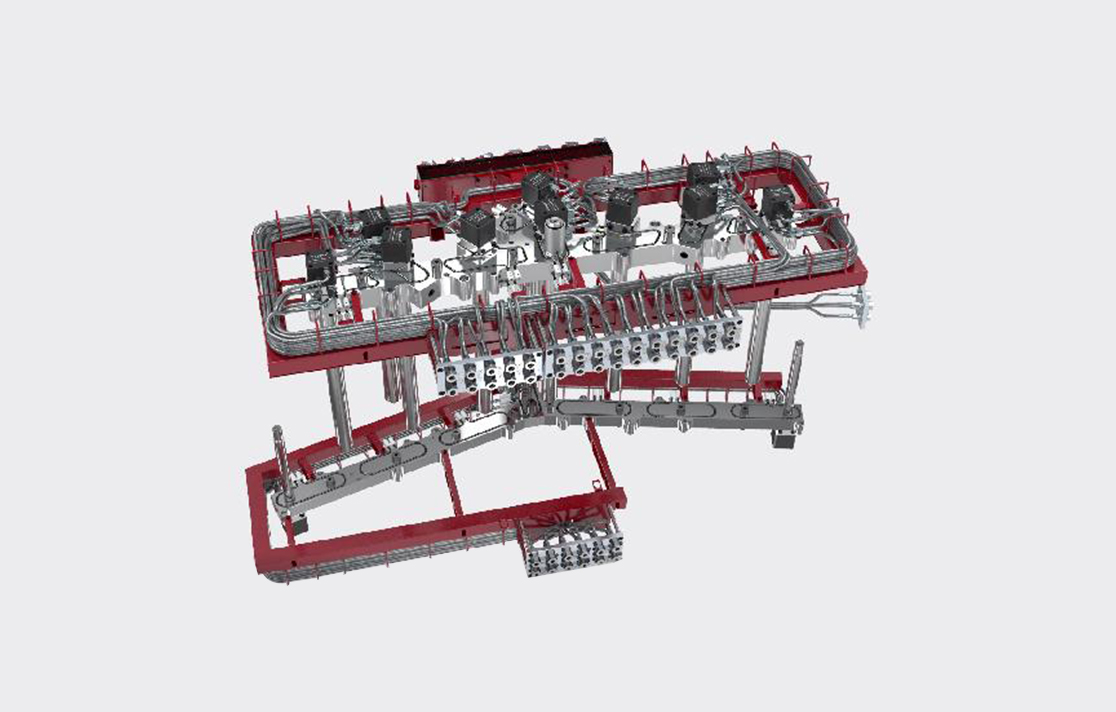

1.Product Introduction

For mass-produced plastic parts, such as daily necessities, plastic products, hot runners be an economical choice. Since there is no additional waste plastic, the hot runner greatly reduces the material cost of the product.

2.Advantages

lThe cost of raw materials is low, and there is no waste recycling, saving runner waste and grinding recycling costs.

lShorten filling time, cooling time, mold opening and closing stroke and molding cycle.

lThe gate part can be automatically separated, saving the time of taking out the runner.

lThe molding temperature and pressure are low, and the stress of the finished product is small.

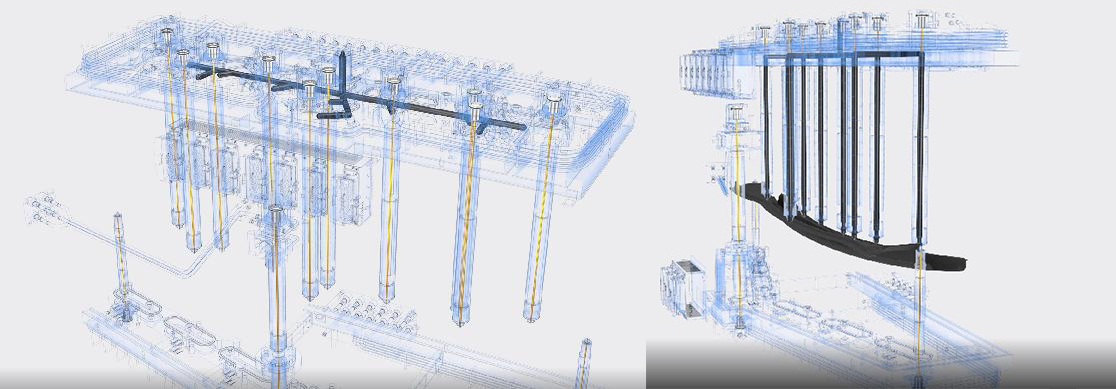

lPrecise control of gate temperature for balanced multi-cavity filling.

lFully automatic molding.

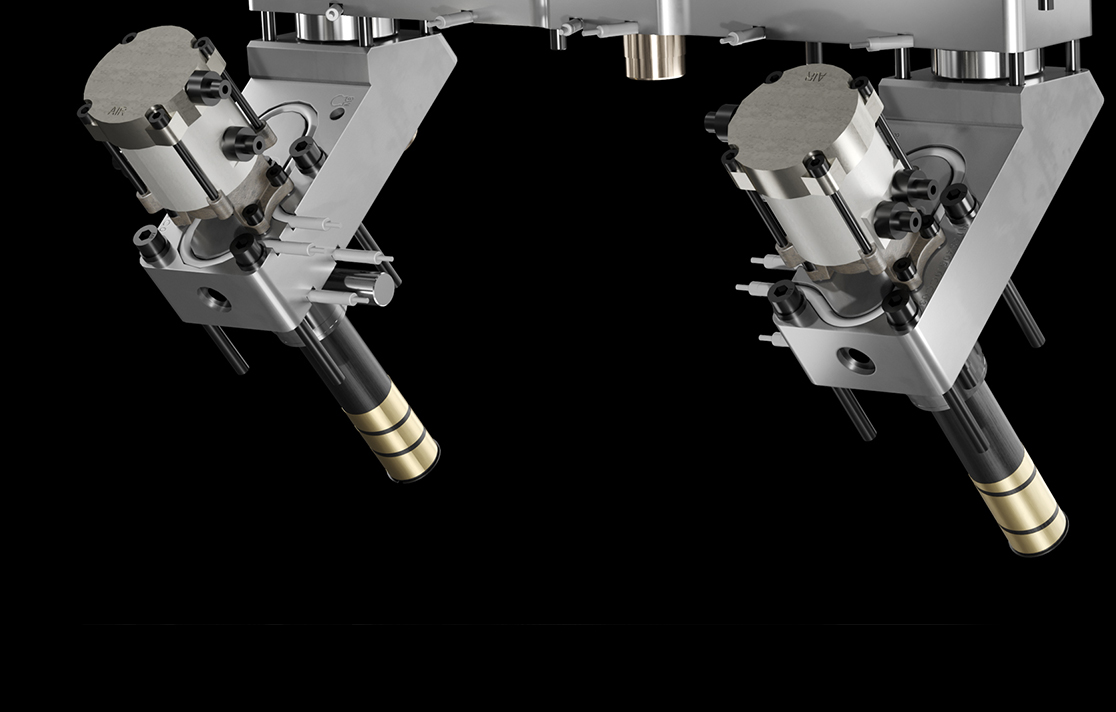

3.Detail

4.Partner

SEND EMAIL TO US

SEND EMAIL TO US